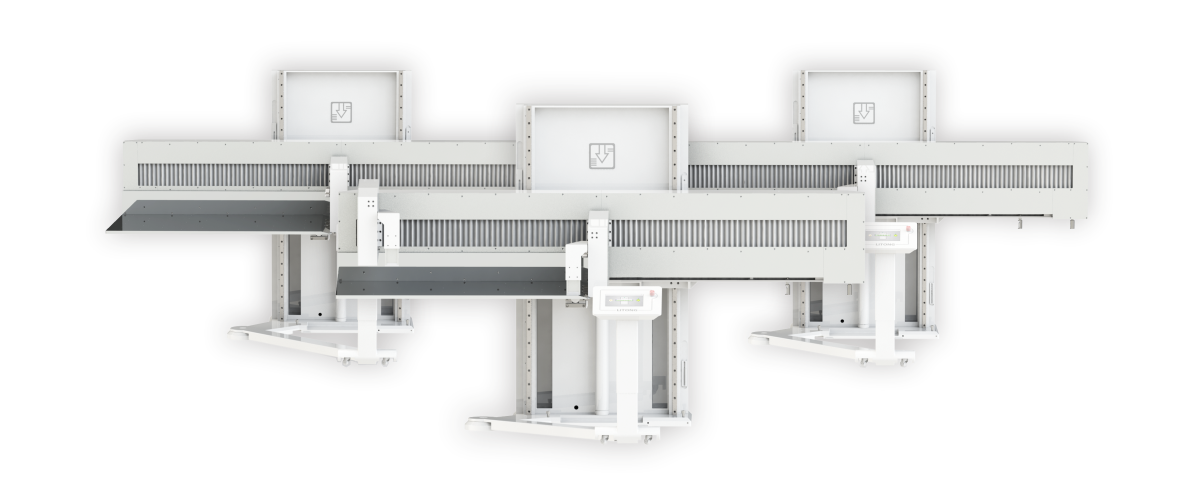

3 models: XZ-S, XZ-A, XZ-I

3 sizes: 950, 1050, 1250 mm

Variety of options for customization

Feature Technologies

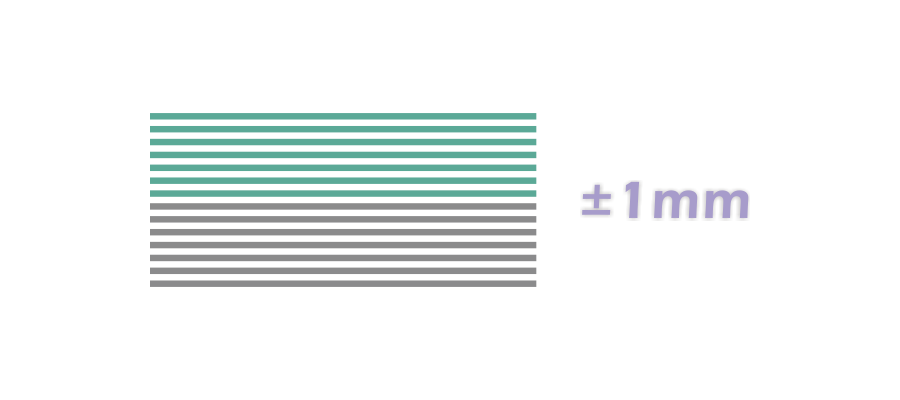

Up to ±1mm Unloading Precision

Ready for direct printing after unloading

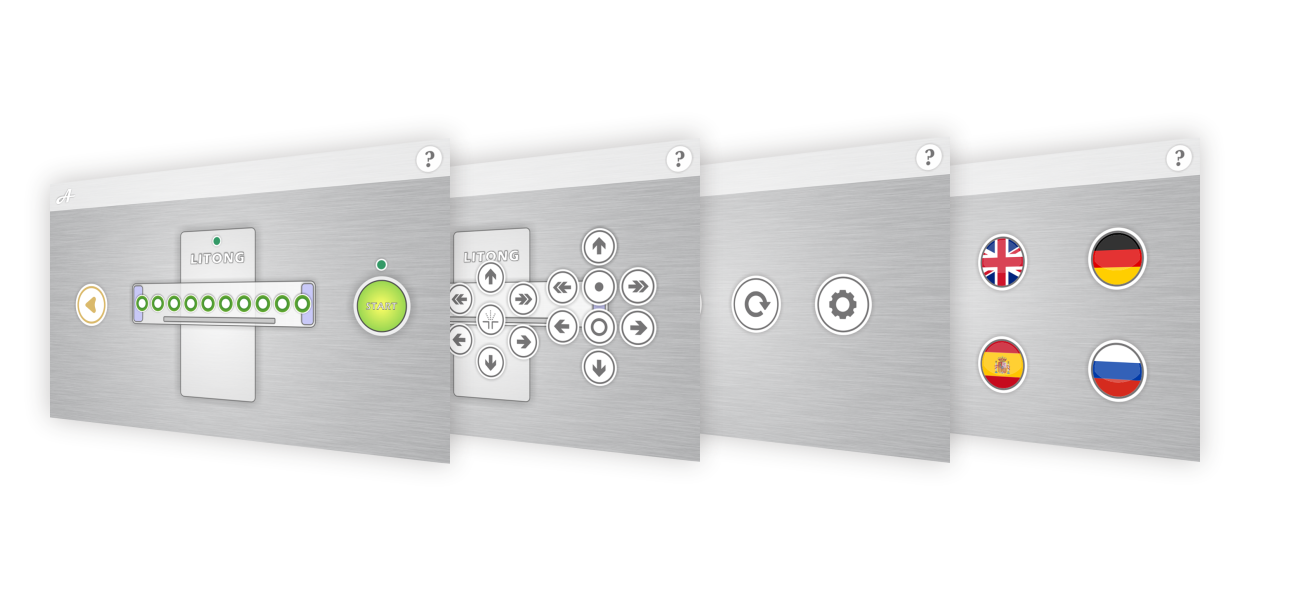

10 Inch Touch Screen

Professional industrial touch panel

Smart-Touch HMI

Exclusive pile unloader operation system

Multi-language User Interface

Support up to 6 languages user interface

Digital Driving System

LITONG customized digital driving system

20m/min High Speed Unloading

Responsive and fast unloading speed

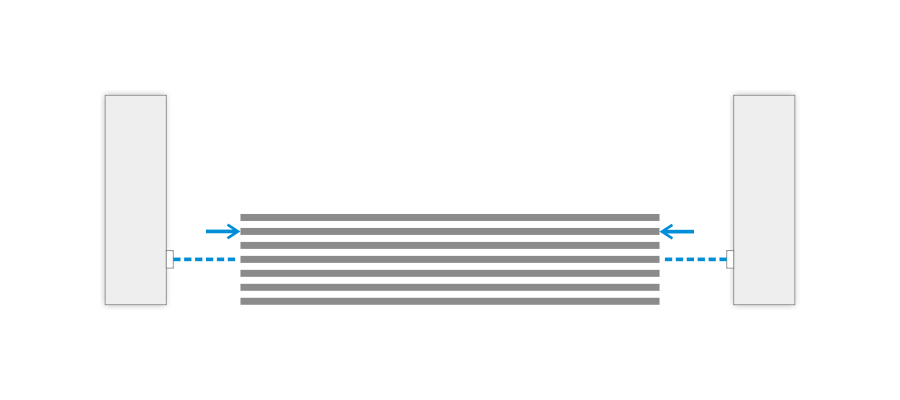

Clamp Unloading System*

Ensure ultra-high unloading precision

Automatic Paper Size Recognition*

No paper size parameter input is needed

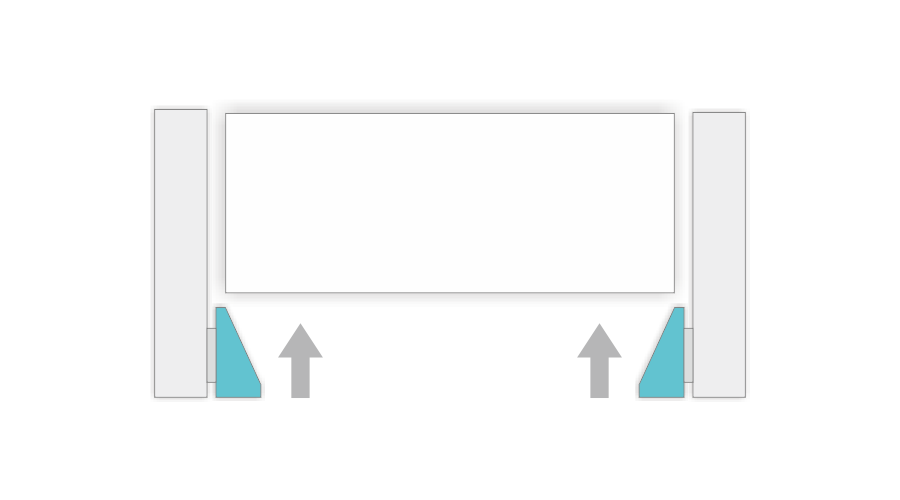

Dual-auxiliary Aligning Arms*

Advanced two-directions aligning technology

One-click Unloading

Super easy one-click unloading operation

One-click Reset

Automatically reset to original position

Production Line Control System

Remote controllable from LITONG paper cutter

Remote Service System

Internet based system service and update

Dynamic self-diagnosis function

Easy to track and diagnose system problem

Table Anti-pinch Safety System

Prevent injury from table movement

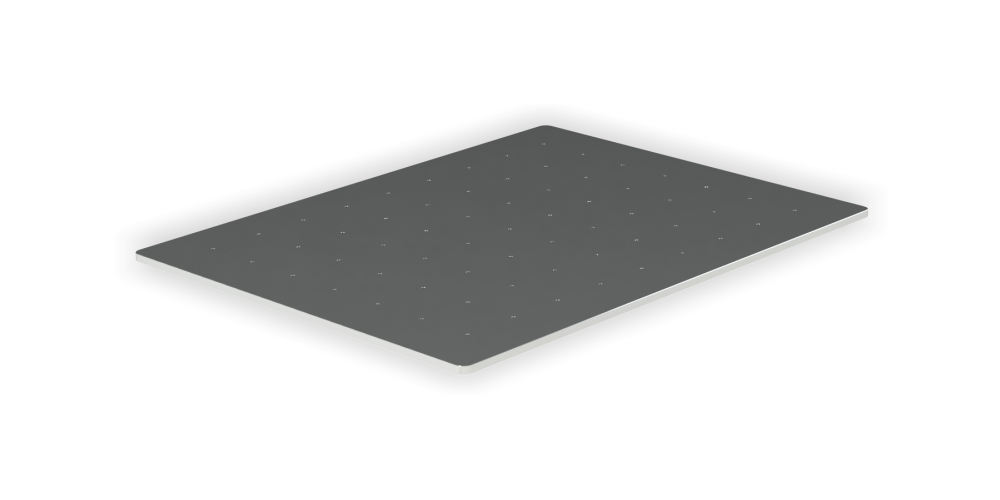

Chromed Steel Working Table

20mm Ultra-slim design with great strength

Automatic Micro-pore Air Cushion

Air cushion is formed only under materials

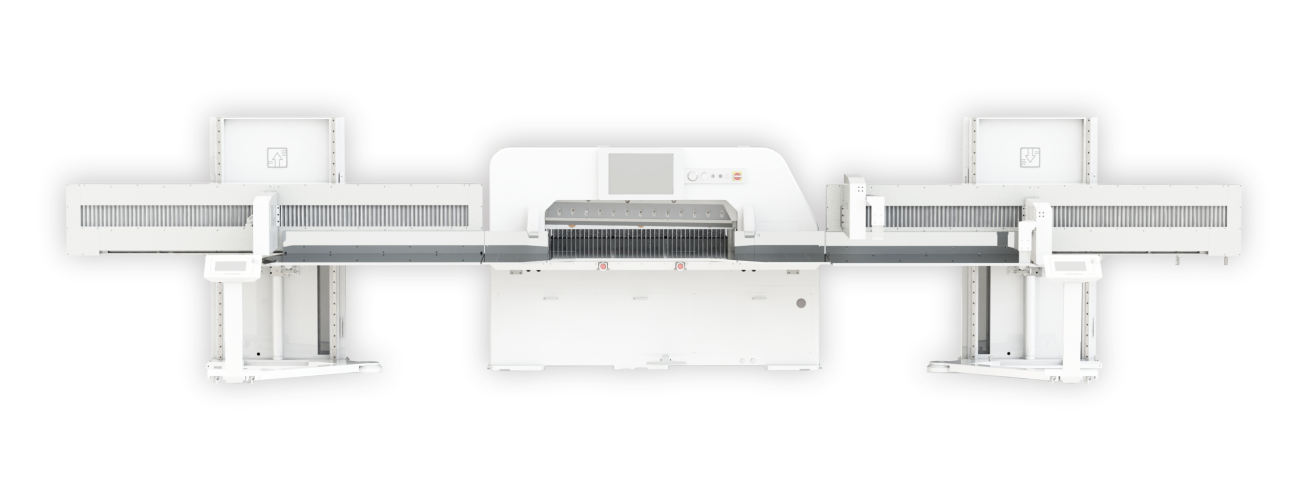

Integral Casting Frame

Great mechanical strength and stability

Hydraulic Lifting System

Save up to 50% energy

Dual-linear Guide Lifting System

Great stability and maintenance free

Movable Control Desk

Multi-direction movable and easy for use

* Configuration or function is different from models

Ultra-high Unloading Precision

Maximum ±1mm unloading precision

Ready for direct printing after unloading

Smart-Touch Operation System

Exclusive operation system designed for pile unloader

One-click unloading and one-click reset function

Multi-language operation system

Production Line Control

Ready for directly control from LITONG paper cutter

Simplify operation of cutting production line and greatly improve productivity

Remote Service

Internet based service system

System diagnose and software update

Advanced P2P communication technology

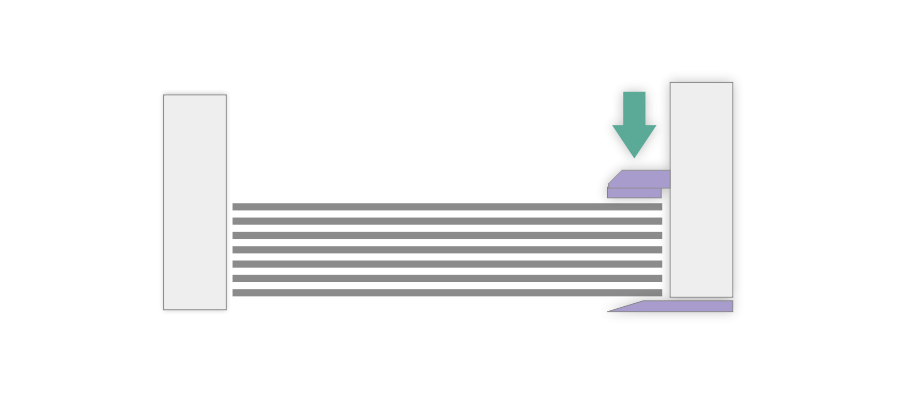

Paper Size Recognition System*

Automatically detects and recognized paper size

No need to input paper size parameter

*Only available on XZ-A and XZ-I Models

Auto-aligning System with Dual-auxiliary Arms*

Two-direction automatic aligning

No need to place paper stack to required position

*Only available on XZ-A and XZ-I Models

Clamp Unloading System*

Prevent paper displacement during unloading

Ensure ±1mm ultra-high unloading precision

Suitable for thin paper stack unloading

*Only available on XZ-S and XZ-I Models

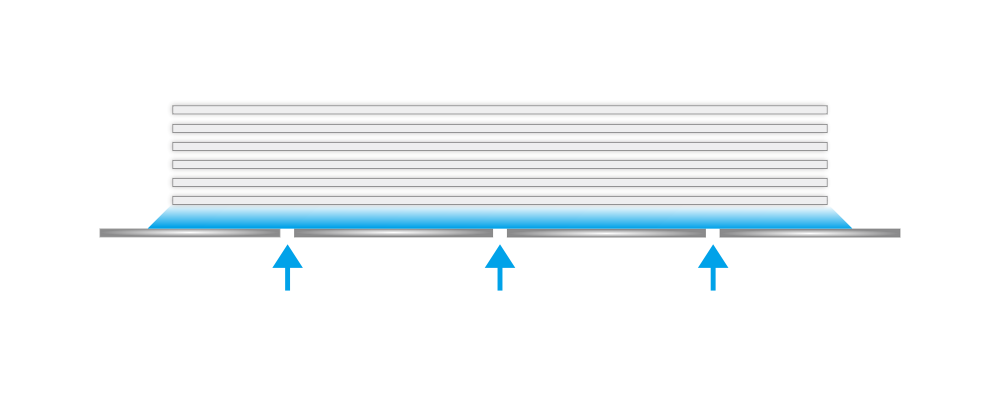

Chromed steel table

20mm slim chromed steel working table

Innovative embedded air chambers carved by CNC technology

Automatic Micro-pore Air Cushion

2mm diameter automatic micro-pore air injector

Air cushion is formed automatically under materials

Up to 25% energy saving and great performance

Hydraulic Lifting System

Hydraulic system only works in lifting period

Up to 50% energy saving compared to traditional pile unloader

Integral Casting Body and Beam

Significantly improve mechanical strength

Eliminate system instability of traditional assembly structure

Dual Linear Guide Lifting System

Greatly improve system working stability

Ensuring long-term unloading precision and maintenance free

Movable Control Desk

Vertical scaling for height adjustment

Horizontal rotation for manual operation and maintenance